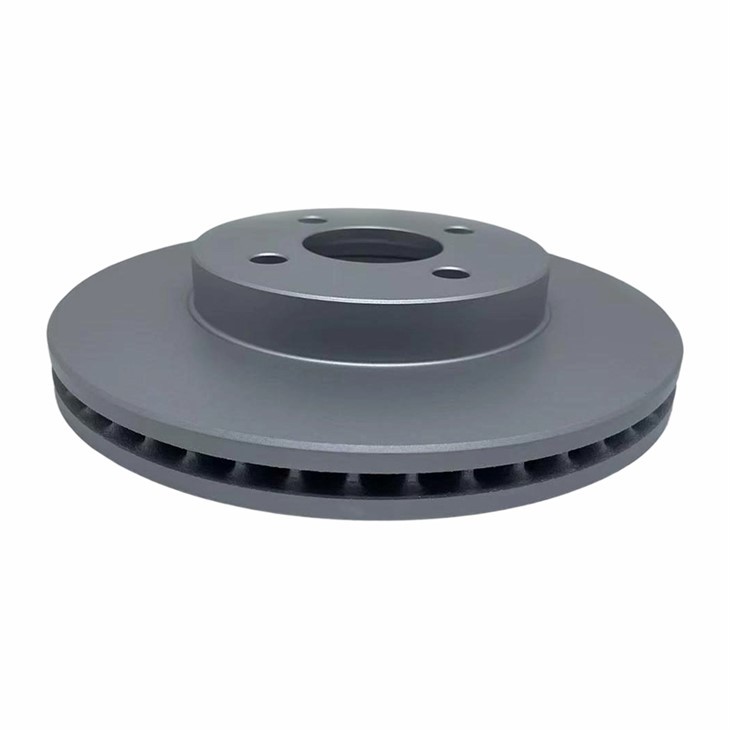

Your Professional Brake Disc Supplier

Jiangsu Qvee Auto Parts Co., Ltd. is a high-tech enterprise specializing in the research, development, manufacturing, and sales of automotive brake pads. In addition to brake pads, the company also manufactures brake discs, spark plugs, filters, brake shoes, and other related automotive components. Its products are widely applied across more than 2,000 vehicle models, ranging from compact passenger cars to heavy-duty trucks.

Professional Team

The company maintains an independent R&D team dedicated to continuously improving the friction material formulation. This ongoing innovation ensures that braking performance consistently exceeds industry standards.

Quality Control

All products undergo rigorous quality inspections, including SPC (Statistical Process Control) online testing for key performance indicators. This ensures stable and reliable product quality, delivering an efficient and safe user experience.

Advanced Equipment

The company is equipped with a comprehensive set of advanced production equipment and technologies, including an automatic batching system, a six-station proportional pressing production line, and a fully automatic CNC processing line.

Sales Market

The brake pads produced by the company are well received in the domestic market and are also exported to Europe. In addition, the company provides supporting and OEM services for both domestic and international automotive manufacturers.

-

BMW Brake DiscBMW Brake Discs are designed for those who pursue the ultimate driving experience and excellent safety performance. They are an indispensable key component in the braking system of BMW vehicles. With

-

Heavy Duty Vehicle Brake DiscsHeavy duty vehicle brake discs are key safety components designed for large trucks, buses and other heavy commercial vehicles. As a core part of the vehicle's braking system, it plays a vital role in

-

Mercedes Brake DiscThe Mercedes Brake Disc made by Qvee Auto Parts are unique in design and feature a ventilated disc design. This design consists of two interconnected discs that are fixed by ribs, creating ample

-

Toyota Floating Carbon BrakeDiscsToyota Floating Carbon BrakeDiscs represent an innovative advancement in brake technology, designed to provide Toyota models with superior braking performance, greater safety and a better driving

-

Ford Brake DiscsFord Brake Discs are one of the high-quality brake system components designed and manufactured specifically for Ford vehicles. As a key component of the vehicle's braking system, the brake disc's

-

Chevy Brake DiscsAs a professional manufacturer of Chevy Brake Discs, Qvee is always committed to providing high-quality, high-performance braking solutions for all Chevrolet models, and protecting the safety of

-

Volvo Brake DiscsOur Volvo Brake Discs products cover Volvo's full range of cars, SUVs, station wagons, etc., and can accurately match the appropriate brake disc. During the R&D and design process, we deeply studied

-

Modified Brake DiscModified Brake Disc are an upgraded component designed to improve the braking performance of vehicles. They are widely used by car enthusiasts who pursue higher handling, safety and driving

-

AUDI Brake DiscThe AUDI Brake Disc made by Qvee are tailor-made for Audi models. They are strictly inspected according to the original factory standards, providing excellent braking response and linear foot feel,

-

Mercedes-Benz Brake DiscMercedes-Benz Brake Discs are key components tailored for car owners who pursue excellent safety and ultimate driving experience, representing Mercedes-Benz's unremitting pursuit of quality and

-

Toyota Brake DiscThe brake disc of a Toyota vehicle is part of the braking system. It is a round metal disc, usually made of cast iron, installed between the wheel and the axle. When the vehicle is moving, the Toyota

-

Heavy Commercial Vehicle Brake DiscsDue to the heavy weight and high load capacity of heavy vehicles, the kinetic energy generated during driving far exceeds that of ordinary vehicles, which places extremely high demands on the braking

Parameter

|

Material |

Ceramic/semi-metal |

|

Friction coefficient |

0.35-0.45 |

|

Attachments |

Gaskets, sensors, as per customer requirements |

|

Dust noise |

No |

|

Application |

Automotive Brake System |

|

Feature |

Dust Long Life Heat Resistant |

Types of Brake Disc

The brake discs produced by our company mainly include the following types:

Car Brake Disc

Disc brakes on a car are a braking system that uses a metal disc (rotor) and brake pads to slow down or stop the vehicle. When the brake pedal is pressed, hydraulic pressure forces brake pads to clamp down on the spinning rotor, creating friction that slows the wheel.

Truck Brake Disc

Truck brake disc, also known as a rotor, is a crucial component of a vehicle's disc brake system, responsible for slowing down and stopping the truck when the brake pedal is pressed. It's a flat, circular metal component that rotates with the wheel and is clamped by brake pads held within a caliper.

Advantages of Brake Disc

Heat Dissipation

One of the primary benefits of brake discs is their superior ability to dissipate heat. Because the brake disc is exposed to air, it cools down much faster than drum brakes, which are enclosed and tend to retain heat. This rapid cooling helps reduce the risk of brake fade, ensuring that braking performance remains stable during extended use or under high loads.

Lightweight Design

Brake discs are generally lighter than drum brakes, which positively impacts the vehicle’s overall weight, improving both fuel efficiency and handling performance. The reduced weight is particularly beneficial in performance vehicles, where agility and responsiveness are crucial.

Ease of Maintenance

Brake discs are easier to inspect and maintain. The brake pads and discs can be visually checked for wear, and replacing worn-out parts is relatively straightforward. This convenience makes brake discs a practical option for both daily drivers and high-performance vehicles.

Reliable in Adverse Conditions

Brake discs are less susceptible to performance issues in wet or muddy conditions compared to drum brakes. This makes them ideal for use in winter or on challenging terrain.

Brake Disc Installation Steps

1. Remove the two bolts that hold the caliper in position and slide the caliper out. If it doesn’t come out easily, use a small pry bar. Use tie clips to hold the caliper on the suspension so it doesn’t put any strain on the brake line and cannot fall.

2. Remove the two bolts on the rear of the hub that hold the caliper carrier in place. These are usually extremely tight, so it’s a good idea to use a breaker bar or an impact gun.

3. Remove the brake pads and inspect them for wear. Apply anti-squeal grease to the backing of the new brake pads. Be careful not to get any grease on the brake discs or friction linings of the brake pads.

4. Check the brake disc for a locating screw and, if there is one, unscrew it before hitting the brake disc with a hammer to remove it.

5. Check the brake disc. Resurface with a crosshatch pattern if still within specifications or replace if the brake disc is too thin to resurface. Resurfacing is usually done at a machine shop or auto parts store.

6. Use a wire brush to clean the rust off the hub to prevent future corrosion.

7. Install the new (or resurfaced) brake disc (including the location screw, if there is one), making sure it sits flush.

8. Replace the calipers (if necessary). Remember to install all bleeder fittings and screws in the upper or top position or it won’t be possible to bleed the brakes later. If you replace the calipers, it’s a good idea to also replace the brake hoses.

9. Replace the carrier bolts and tighten them with a breaker bar or impact gun.

10. Use the C-clamp and an old brake pad to compress the caliper piston until it is flush with the housing of the caliper. Remember to cap off the brake reservoir to reduce the risk of blowing a line and to prevent contamination from entering the line. Clean up any brake fluid that may have come out of the reservoir as brake fluid can damage or remove the paint on your car if it’s not cleaned up quickly.

11. Install the brake pads in the carrier and place the caliper back into the carrier.

12. Remove the brake fluid reservoir cap to ensure any pressure that has built up can escape. Use a G-clamp to push the caliper piston back in so it is flush with the caliper. Install and tighten the caliper bolts.

13. Check that the brake disc can move freely without the brakes being applied.

14. Repeat these steps for all of the brake discs you need to replace. Remember that you need to replace brakes in pairs (either the front pair or the rear pair) to ensure even braking.

1. Ordering

2. Mold Design

3. Core Making

4. Modeling and Melting

5. Spectral Analysis

6. Sand Casting and Cleaning

7. Mechanical Analysis

8. Processing

9. Dynamic Balance

10. Marking and Spraying

11. Inspection

12. Cleaning and Packaging

13. Warehousing and Delivery

Packaging and Shipping

|

Packaging |

Generally, we pack our goods in neutral packing box. We also can pack as your demand. |

|

Shipping |

Shipping by sea, by air, by express are acceptable. According to your requirements. |

Our Factory

The company covers an area of 150 mu, with a total construction area of 80,000 square meters for factories, office buildings, staff dormitories and other facilities. Not only is the space vast, but the planning is also reasonable, providing a good environment for efficient production and office work.

Our Certificate

JiangSu Qvee Auto Parts Co., Ltd. has obtained a number of important qualifications and certifications, such as China Compulsory CCC Certification and EU Emark Certification, proving that the products have met the strict requirements of national standards and international markets.

FAQ

As one of the leading brake disc manufacturers and suppliers in China, we warmly welcome you to buy cheap brake disc from our factory. All customized products are with high quality and competitive price. Contact us for quotation.